HVAC cleaning tools are the backbone of professional air system maintenance. Without the right equipment, technicians can’t effectively remove contaminants and ensure optimal indoor air quality.

At Cleaning Rabbit, we’ve seen firsthand how proper tools can make or break an HVAC cleaning job. This guide will explore the essential equipment every HVAC cleaning professional should have in their arsenal.

Power Tools for Pristine Ducts

HVAC cleaning professionals need robust equipment to tackle the toughest jobs. High-powered HEPA vacuum systems and portable air compressors are the workhorses of duct cleaning.

HEPA Vacuum Systems: The Core of Duct Cleaning

HEPA vacuum systems are essential for top-notch air duct cleaning. These powerhouses capture up to 99.97% of particles as small as 0.3 microns. The National Air Duct Cleaners Association (NADCA) recommends vacuums with HEPA filtration to prevent contaminants from re-entering the air during cleaning.

Truck-mounted systems offer the most power and capacity for large commercial jobs. For residential work, portable HEPA vacuums with at least 1,000 CFM (cubic feet per minute) airflow provide excellent results.

Portable Air Compressors: Accessing Every Corner

Portable air compressors dislodge stubborn debris in hard-to-reach areas. Air compressors typically use a diesel or electric drive to operate, with options available for both. Diesel drives can generally handle 185 CFM, ensuring enough power to operate air whips and other pneumatic tools effectively.

The key is to balance power with portability. A 185 CFM compressor (typically weighing around 2,000 pounds) suits truck mounting. For more accessible jobs, a smaller 90 CFM unit can be wheeled into buildings.

Filtration: The Silent Guardian of Clean Air

Proper filtration in vacuum systems maintains indoor air quality during and after cleaning. HEPA filters are the gold standard, but they’re not the whole story.

Pre-filters extend the life of your HEPA filter by capturing larger particles first. Replace pre-filters regularly – check them after every job and replace at least monthly.

For the main HEPA filter, follow the manufacturer’s guidelines. They typically need replacement every 6-12 months (depending on usage). Don’t skimp here – a compromised HEPA filter can release contaminants back into the air, undoing all your hard work.

Quality vacuum systems and compressors improve efficiency and client satisfaction. Well-maintained equipment allows professionals to tackle even the dirtiest ducts with confidence. Now, let’s explore the specialized brushes and agitation tools that complement these power tools for a thorough HVAC cleaning process.

Brushes and Agitation Tools for Effective Duct Cleaning

Rotating Brushes: The Powerhouses of Duct Cleaning

Rotating brush systems stand as the primary tools for most duct cleaning jobs. These brushes come in various sizes and materials to match different duct types. Metal ducts require nylon-bristled brushes for effective cleaning without damage. Fiberglass ducts need softer bristles to prevent scratching.

The effectiveness of these brushes depends on matching their size to the duct diameter. A brush that’s too small won’t contact the duct walls properly, while an oversized brush can get stuck or damage the ducts. Professionals typically keep a range of sizes on hand (usually from 4 to 24 inches in diameter).

Brush rotation speed plays a critical role in cleaning efficiency. Professionals should start with a lower speed and increase as necessary.

Whip Lines: Tackling Hard-to-Reach Areas

Whip lines (also known as air whips) prove invaluable for cleaning areas that brushes can’t effectively reach. These flexible tools use compressed air to create a whipping action that dislodges debris from duct surfaces.

Air whips excel in:

- Flex ducts where rigid brushes might cause damage

- Tight corners and bends in the ductwork

- Large diameter ducts where brushes might not provide enough agitation

Proper air pressure maintenance is essential when using air whips. Insufficient pressure won’t effectively dislodge debris, while excessive pressure can damage ducts. Most professionals use between 90 to 150 PSI, adjusting based on the specific duct material and condition.

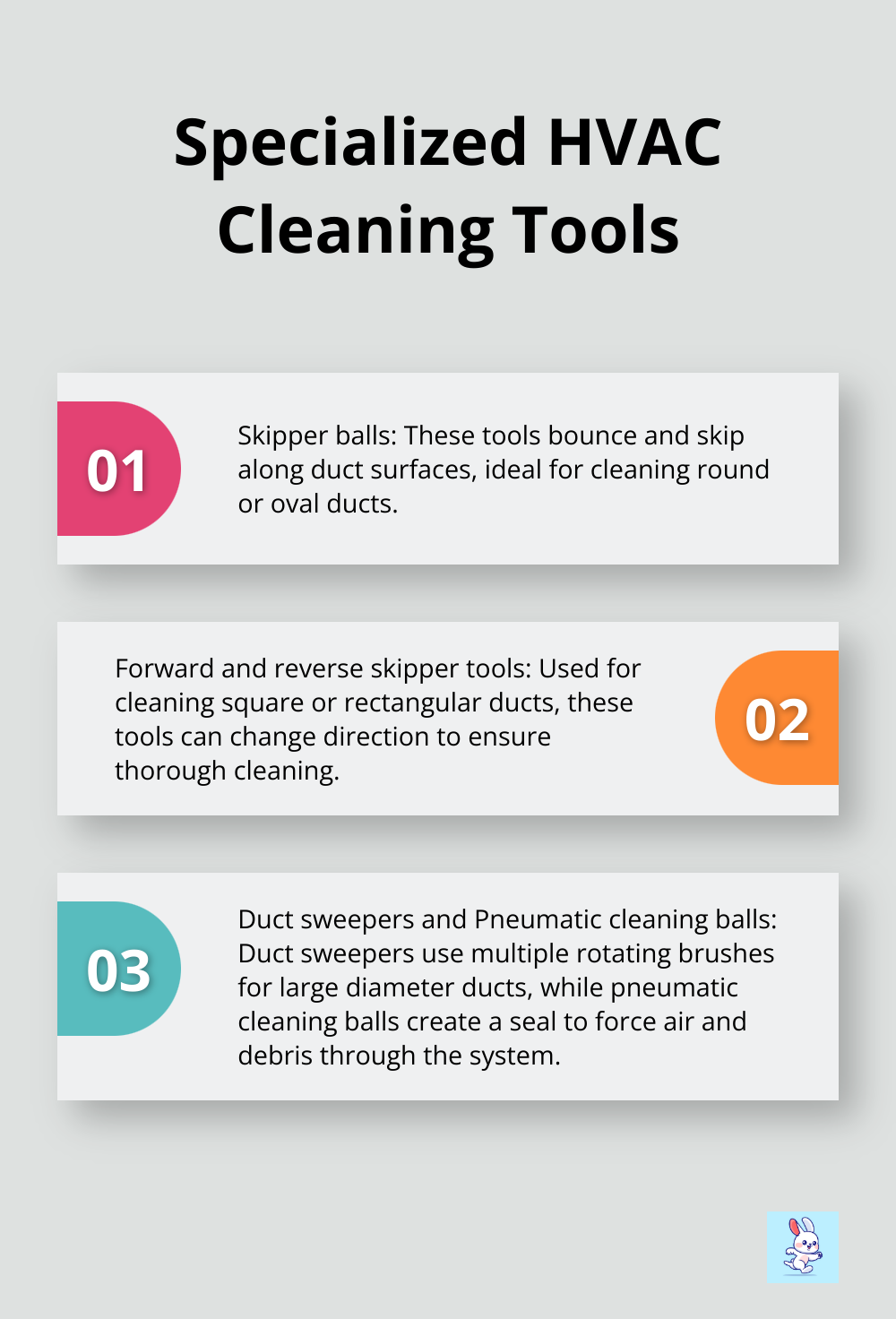

Specialized Tools for Unique Situations

While rotating brushes and whip lines handle most jobs, some situations call for specialized tools:

Insulating, air sealing, and placing ducts within the conditioned space of your home will reduce energy losses. Using the right combination of these specialized tools ensures that every nook and cranny of the duct system receives a thorough cleaning, maximizing energy efficiency and indoor air quality.

The effectiveness of these tools relies heavily on proper training and technique. NADCA offers certification programs that cover the correct use of these specialized cleaning tools (ensuring professionals can deliver top-notch results).

As we move forward, let’s explore the chemical cleaning products and sanitizers that complement these physical cleaning tools, providing a comprehensive approach to HVAC system maintenance.

Chemical Cleaning: Enhancing HVAC Sanitation

EPA-Approved Disinfectants: Setting the Standard

The Environmental Protection Agency (EPA) establishes strict standards for disinfectants used in HVAC systems. These products must kill a wide range of pathogens without risking human health or the environment. The EPA’s List N catalogs disinfectants effective against SARS-CoV-2, serving as an excellent resource for HVAC professionals.

When selecting a disinfectant, consider its dwell time (the period it must remain wet on a surface to be effective). Products with shorter dwell times (1-3 minutes) often work better for HVAC applications. Always follow manufacturer instructions for dilution and application to achieve optimal results.

Fogging Machines: Thorough Distribution

Fogging machines have transformed the application of sanitizers in HVAC systems. These devices create a fine mist of disinfectant that penetrates hard-to-reach areas of ductwork. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends foggers with particle sizes between 10-50 microns for optimal coverage and surface adherence.

Proper calculation of solution amount based on ductwork volume is essential when using a fogger. Overapplication can cause moisture issues, while underapplication may not disinfect adequately. Try using about 1 ounce of solution per 1,000 cubic feet of duct space (but always consult specific product guidelines).

Eco-Friendly Solutions: Meeting Client Demands

The demand for environmentally friendly cleaning products continues to grow. A Nielsen global online survey found that 66 percent of consumers are willing to pay more for sustainable brands. This trend extends to HVAC cleaning, with clients increasingly requesting green alternatives to traditional chemical cleaners.

Hydrogen peroxide-based cleaners have become a popular eco-friendly option. These products break down into water and oxygen, leaving no harmful residues. Some formulations include silver ions for enhanced antimicrobial properties (though they may require longer contact times compared to conventional disinfectants).

Plant-based enzymatic cleaners offer another green alternative. These products use natural enzymes to break down organic matter and eliminate odors. They work particularly well for addressing mold and mildew issues in HVAC systems.

When choosing eco-friendly solutions, look for third-party certifications such as Green Seal or EcoLogo. These certifications ensure products meet rigorous environmental and performance standards. Even natural products can cause irritation or allergic reactions in some individuals, so proper safety precautions remain necessary.

To ensure the best results, it’s crucial to choose the best HVAC system cleaning services that are experienced in using these chemical cleaning tools effectively and safely.

Final Thoughts

Quality HVAC cleaning tools empower professionals to tackle challenging tasks efficiently. These tools reduce cleaning time, increase productivity, and lead to higher customer satisfaction. Professionals who invest in the right equipment can achieve superior results and address even hard-to-reach areas within duct systems.

The HVAC cleaning industry constantly evolves with new technologies and techniques. Professionals must stay updated through industry certifications, workshops, or self-study to remain competitive. Mastering new tools and understanding the latest best practices will help HVAC cleaning professionals deliver exceptional results.

Cleaning Rabbit uses cutting-edge HVAC cleaning tools to provide superior air quality solutions in Las Vegas and Henderson. Our team combines expertise with state-of-the-art equipment (including specialized brushes, HEPA vacuums, and eco-friendly cleaning solutions) to ensure every job meets the highest standards of quality and safety. We strive to create healthier, more comfortable indoor environments for our clients through our comprehensive HVAC cleaning services.